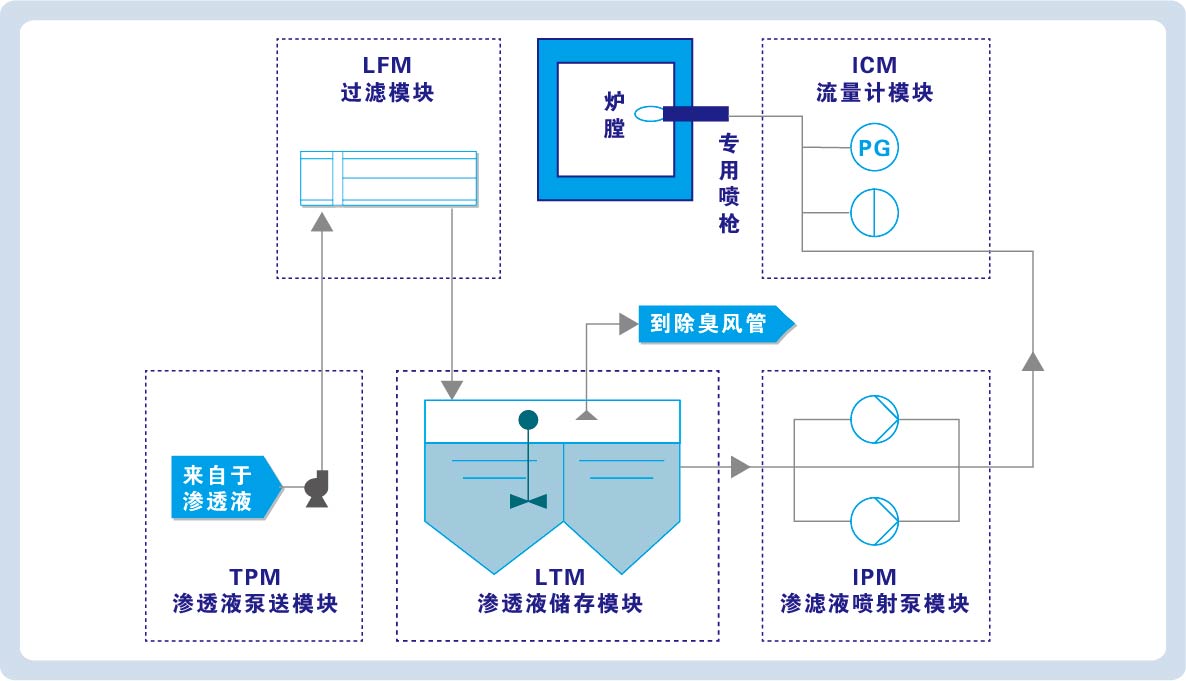

The leachate generated in garbage incineration power generation is a highly concentrated sewage with complex components, which is difficult to degrade. Leachate spray back is a treatment method that sprays the leachate back into the incinerator for incineration. It is an effective way of treating leachate and can effectively reduce the furnace temperature of the incinerator and reduce the amount of coking in the furnace;

Compared to advanced treatment processes such as nanofiltration and reverse osmosis, the leachate backflow process has the advantages of simple process, mature technology, low investment cost, small footprint, and low maintenance cost

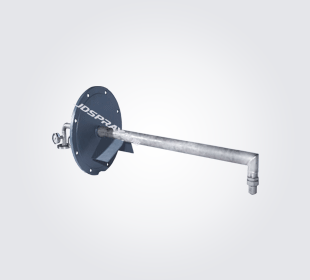

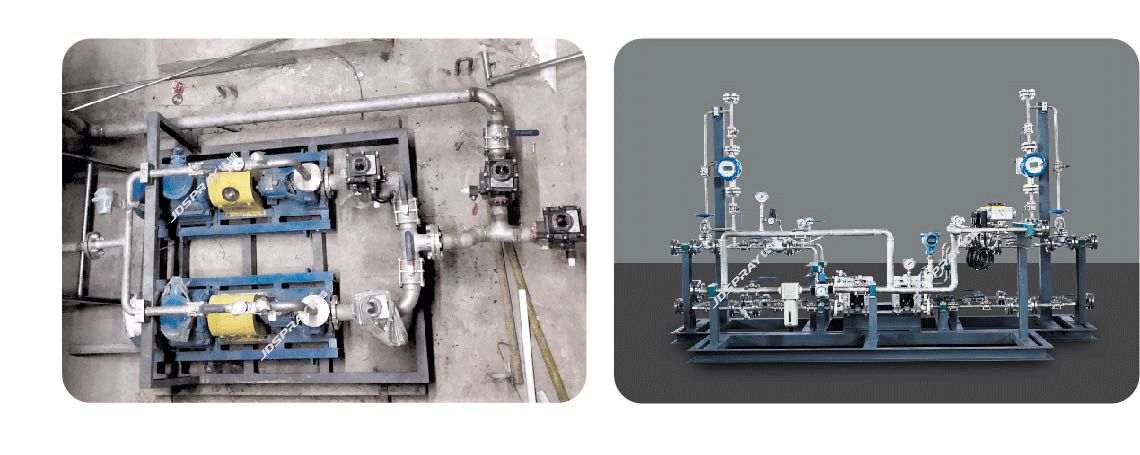

The leachate backflow system developed by Shanghai Jiadi has independent core technology, which does not require manual operation and automatically controls the temperature and spray amount of the furnace. It has been widely used in projects such as Shenzhen East Environmental Protection Power Plant, Huazhou Shenneng Environmental Protection Co., Ltd., Suzhou Sixian Shenneng Environmental Protection Co., Ltd., Yutai Shenneng Environmental Protection Co., Ltd., Dingtao District Shenneng Environmental Protection Co., Ltd., and Shaoxing Circular Ecological Industrial Park Phase II Incineration Plant, And customized supply can be made according to the different needs of customers.

For more information, please call 021-5899 4026.

Spray Systems Solution Provider

Spray Systems Solution Provider

Service Hotline:4001 123 933

Service Hotline:4001 123 933