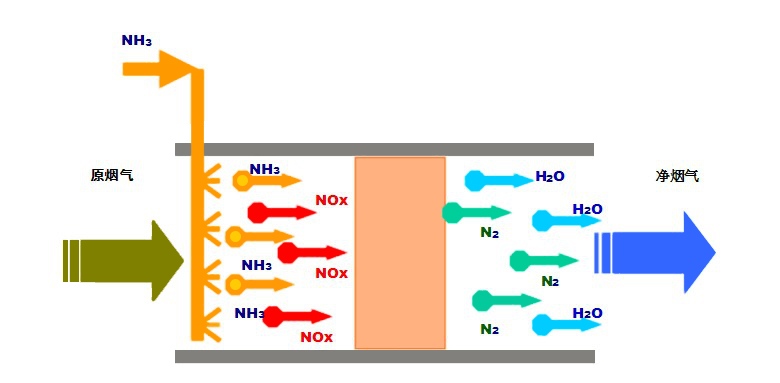

1. Reaction chamber The reaction chamber is an external structure for placing catalysts, mainly composed of a frame steel structure and a closed space welded with steel plates. Install a catalyst replacement door, a manhole door, and a hole for installing a sonic soot blower on the reaction chamber shell. In the reaction chamber, the reducing agent (ammonia) reacts with nitrogen oxides in the flue gas under the action of a catalyst to generate harmless nitrogen and water vapor, thereby removing NOx from the flue gas.

2. Catalyst

Catalysts are composed of ceramic supports and vanadium titanium based active ingredients. Currently, popular mature catalysts include honeycomb, corrugated, and flat plates. Honeycomb catalysts are formed by extruding a mixture of support and active ingredients as a whole; The corrugated catalyst has a wavy appearance, forming small pores. Flat plate catalysts are made of stainless steel metal mesh as the substrate, loaded with a carrier containing active ingredients, and pressed; The performance of an SCR system is mainly determined by the quality of the catalyst and reaction conditions. The larger the catalyst volume, the higher the NOx removal efficiency, and the less ammonia escapes.

3. Flue system The flue system is divided into two parts: the inlet flue of the reactor and the outlet flue. An ammonia injection device, tubular mixer, flue gas guide plate, and ash hopper are arranged on the inlet flue, and flue gas guide plate is arranged on the outlet flue.

4. Storage and conveying system The storage and transportation system mainly consists of a discharge compressor, storage tank, evaporation tank, buffer tank, and transportation pipeline, and is equipped with a nitrogen blowing system. The reducing agent is transported by tank trucks and stored in liquid form in storage tanks. Before being sprayed into the flue gas, the reducing agent is evaporated and gasified by the evaporator, and then supplied to the reactor after being stabilized by a buffer tank.

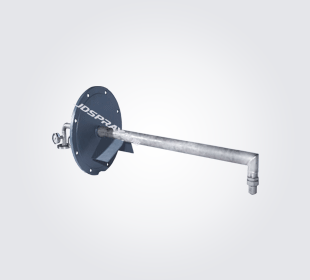

5. Injection system The injection system consists of a dilution fan, a mixer, and an ammonia spray grille. It mixes the gasified reducing agent with dilution air and sprays it into the flue gas upstream of the reactor through the ammonia spray grille.

6. Soot blowing system

The reactor adopts acoustic soot blowing, and each reactor is equipped with a set of acoustic soot blowing system. The control of the soot blower is connected to the DCS system.

For more information, please call 021-5899 4026.

Spray Systems Solution Provider

Spray Systems Solution Provider

Service Hotline:4001 123 933

Service Hotline:4001 123 933