Selective Catalytic Reduction (SCR) is currently the most widely used denitrification technology in industry. The NOx emission control applied to combustion equipment such as power plant boilers, industrial boilers, and garbage incineration can ideally achieve a NOx removal efficiency of over 90%. It is currently one of the most widely used and mature technologies. The reaction principle of low-temperature SCR is to use reducing agents such as ammonia or urea to selectively decompose NOx in the flue gas into harmless nitrogen (N2) and water (H2O) through the action of catalysts at a certain temperature, thereby reducing the concentration of NOx in the flue gas. In addition, through catalytic action, dioxins (DXNs) in flue gas can be decomposed into harmless carbon dioxide, water, and trace amounts of hydrogen chloride.

The basic principle of SCR denitrification process can be expressed by the following equation:

4NH3+4NO+O2 → 4N2+6H2O

8NH ₂+6NO ₂ → 7N ₂+12H ₂ O

The basic principle of SCR for removing dioxins can be expressed by the following equation:

C12H4O2CL4+11O2 → 12CO2+4HCL

C12H4OCL4+23/2O2 → 12CO2+4HCL

By using appropriate catalysts, the above reaction can be effectively carried out within the temperature range of 200 ℃ -450 ℃. Under ideal ammonia nitrogen ratio conditions, the flue gas denitrification efficiency can reach 80% -90%.

The efficiency of SNCR denitrification technology is generally not less than 80%. Compared with SNCR denitrification technology, the specific characteristics are as follows:

Mature and reliable technology with high denitrification efficiency;

Low ammonia escape reduces secondary pollution;

Fast reaction speed, low conversion rate of SO ₂/SO ₂, reducing corrosion and blockage of equipment;

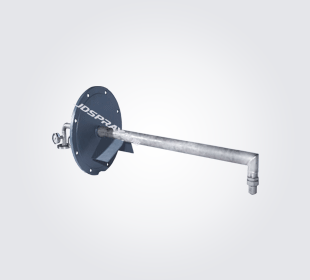

Uniform ammonia spraying, low resistance, low ammonia consumption, and low operating costs;

Suitable for denitrification of low-temperature flue gas.

Spray Systems Solution Provider

Spray Systems Solution Provider

Spray Systems Solution Provider

Spray Systems Solution Provider